Difference between revisions of "GX:Studio:Catchweight"

m |

|||

| (14 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

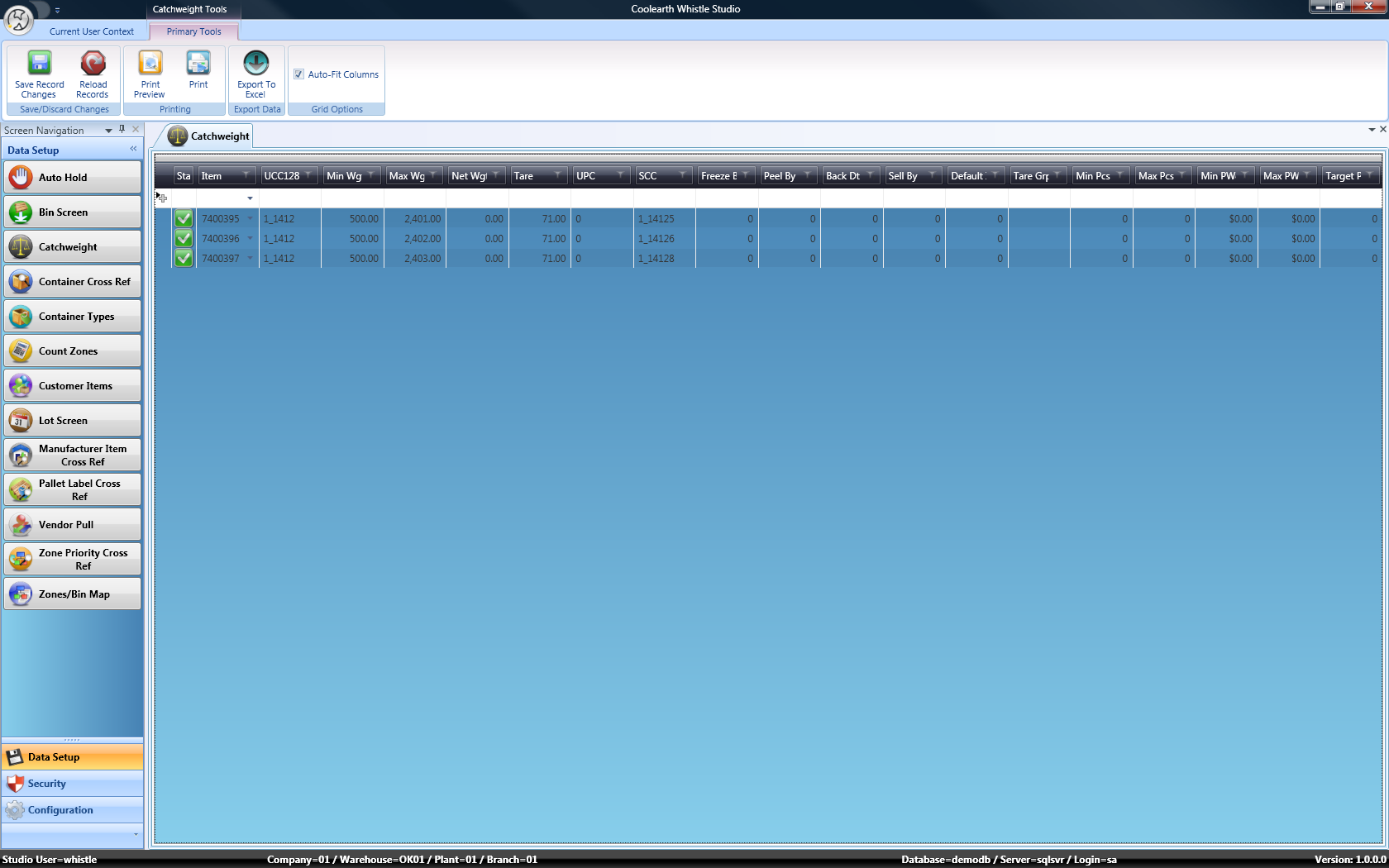

| − | [[Image:Catchweight.png|thumb| | + | [[Image:Catchweight.png|thumb|1000px|Image:Catchweight.png|thumb|1000px]] |

| + | |||

| + | ==Security== | ||

| + | In order to use this screen, the user must have been assigned the screen privilege "SD CATCHWEIGHT SETUP". | ||

| + | |||

| + | |||

| + | ==Access== | ||

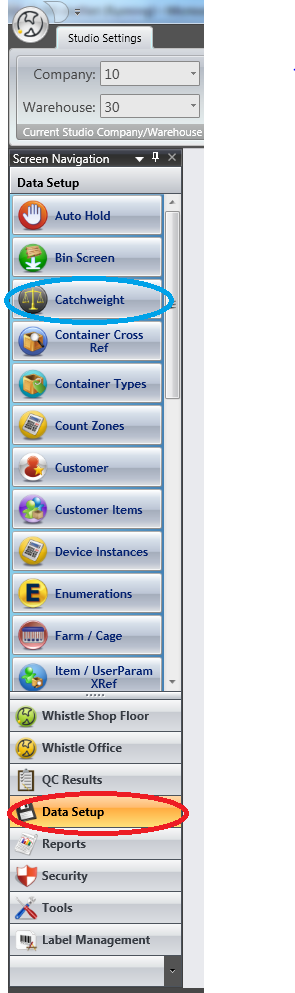

| + | Log into Studio. On the menu on the left hand side, select "Data Setup" (see picture below, in red). Pressing that button will display a menu of data items that you have permission to set up. From that list, select "Catchweight" (see picture below, in blue). Press that button, and you will see the Catchweight table maintenance screen. | ||

| + | |||

| + | |||

| + | [[Image:CWMenu.PNG|Image:CWMenu.PNG]] | ||

| + | |||

==Intended Use== | ==Intended Use== | ||

| − | + | This screen is used to set up catchweighted items in Whistle. A catchweighted (also known as random weight) item is inventory where each piece can have a different weight, and the product is priced by the actual weight of the individual piece. In contrast, a standard weight (also known as net weight) item is one that uses the same (standardized) weight for each piece. | |

| + | |||

| + | ==ERP System== | ||

| + | ===Infor=== | ||

| + | If you are using Infor, you need to have set up the item/pack inventory as sublotted; that is, created an entry in the in_sublot_tbl. You also need to set the fill attribute column (in_itmpk_fillattr) in the in_itmpk_tbl to a value of 2. | ||

| + | |||

| + | |||

==Example Usage== | ==Example Usage== | ||

| − | New Item #23 is catchweighted, and Whistle needs to know the various | + | New Item #23 is catchweighted, and Whistle needs to know the various weights associated with the item. |

| + | |||

| + | |||

==Columns== | ==Columns== | ||

| − | === | + | There are certain rules associated with entries made in some columns. This will provide an overview of what is required to be in the various columns of this table. |

| − | The item to be catchweighted | + | |

| − | === | + | ===in_item_key=== |

| − | === | + | The item to be catchweighted. |

| − | Minimum allowable weight of the item | + | |

| − | === | + | ===im_pack_key=== |

| − | Maximum allowable weight of the item | + | This is the pack entry of item to be catchweighted. Catchweighted items must have an entry in this column. Items without pack entries are, generally, considered to be bulk inventory. |

| − | === | + | |

| − | Net weight of the item | + | ===ucc128_item=== |

| − | === | + | This is a unique item number, used to map the item from the vendor to the item in the ERP system. |

| − | Weight of packaging | + | |

| − | === | + | ===wms_ctwght_minwgt=== |

| − | === | + | Minimum allowable weight of the item. This entry must be less than or equal to the maximum weight of the field. When there is a value in this field, the netweight field must be 0, and the maximum weight field must be filled out. |

| − | === | + | |

| − | === | + | ===wms_ctwght_maxwgt=== |

| − | === | + | Maximum allowable weight of the item. This entry must be greater than or equal to the minimum weight of the field. When there is a value in this field, the netweight field must be 0, and the minimum weight field must be filled out. If the ERP system you are using is Infor, this value also cannot be larger than the maximum case weight set up in the ERP system. |

| − | === | + | |

| − | === | + | ===wms_ctwght_netwt=== |

| − | === | + | Net weight of the item. When there is an entry in this field, the minimum and maximum weight fields must be 0. |

| − | === | + | |

| − | === | + | ===wms_ctwght_tare=== |

| − | === | + | Weight of the packaging material used for packaging this item/pack. This is the amount to be removed from the total weight of the packages item in order to find the actual weight of just the inventory. |

| − | === | + | |

| − | === | + | ===upc_key=== |

| + | Typically unused. This value now comes from the ERP system. | ||

| + | |||

| + | ===wms_ctwght_scc=== | ||

| + | Typically unused. This value now comes from the ERP system. | ||

| + | |||

| + | ===wms_ctwght_freeze=== | ||

| + | This is the number of days to offset the production date for freeze. | ||

| + | |||

| + | ===wms_ctwght_peel=== | ||

| + | This is the number of days to offset the production date for peel. | ||

| + | |||

| + | ===wms_ctwght_backdt=== | ||

| + | This is the number of days to offset the production date backwards for backdating. | ||

| + | |||

| + | ===wms_ctwght_sell=== | ||

| + | This is the number of days to offset the production date for sellby. | ||

| + | |||

| + | ===defaultitem=== | ||

| + | Customer specific entry, not generally used. | ||

| + | |||

| + | ===boxcode=== | ||

| + | An entry that permits containers with the same inventory contents to track the tares by tare-group instead of by the item. Customer specific entry, not generally used. | ||

| + | |||

| + | ===minPieces=== | ||

| + | This is the minimum number of pieces permitted per case. | ||

| + | |||

| + | ===maxPieces=== | ||

| + | This is the maximum number of pieces permitted per case. | ||

| + | |||

| + | ===minPieceWeight=== | ||

| + | This is the mMinimum average pieceweight for case (average pieceweight is case netweight / # pieces). | ||

| + | |||

| + | ===maxPieceWeight=== | ||

| + | This is the maximum average pieceweight for case. | ||

| + | |||

| + | ===target_pieces=== | ||

| + | This is the target number of pieces (how many you're trying to pack) for a case. | ||

| + | |||

===ECOLotsOnly=== | ===ECOLotsOnly=== | ||

| − | + | This marks an item for being in an ECO certification. ECO lots are only permitted to use ECO item. (Customer specific entry) | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

[[GX:Category:Studio Screen|Category:Studio Screen]] | [[GX:Category:Studio Screen|Category:Studio Screen]] | ||

[[GX:Category:Data Setup|Category:Data Setup]] | [[GX:Category:Data Setup|Category:Data Setup]] | ||

[[GX:Category:WIP|Category:WIP]] | [[GX:Category:WIP|Category:WIP]] | ||

Latest revision as of 15:58, 12 February 2013

Contents

- 1 Security

- 2 Access

- 3 Intended Use

- 4 ERP System

- 5 Example Usage

- 6 Columns

- 6.1 in_item_key

- 6.2 im_pack_key

- 6.3 ucc128_item

- 6.4 wms_ctwght_minwgt

- 6.5 wms_ctwght_maxwgt

- 6.6 wms_ctwght_netwt

- 6.7 wms_ctwght_tare

- 6.8 upc_key

- 6.9 wms_ctwght_scc

- 6.10 wms_ctwght_freeze

- 6.11 wms_ctwght_peel

- 6.12 wms_ctwght_backdt

- 6.13 wms_ctwght_sell

- 6.14 defaultitem

- 6.15 boxcode

- 6.16 minPieces

- 6.17 maxPieces

- 6.18 minPieceWeight

- 6.19 maxPieceWeight

- 6.20 target_pieces

- 6.21 ECOLotsOnly

Security

In order to use this screen, the user must have been assigned the screen privilege "SD CATCHWEIGHT SETUP".

Access

Log into Studio. On the menu on the left hand side, select "Data Setup" (see picture below, in red). Pressing that button will display a menu of data items that you have permission to set up. From that list, select "Catchweight" (see picture below, in blue). Press that button, and you will see the Catchweight table maintenance screen.

Intended Use

This screen is used to set up catchweighted items in Whistle. A catchweighted (also known as random weight) item is inventory where each piece can have a different weight, and the product is priced by the actual weight of the individual piece. In contrast, a standard weight (also known as net weight) item is one that uses the same (standardized) weight for each piece.

ERP System

Infor

If you are using Infor, you need to have set up the item/pack inventory as sublotted; that is, created an entry in the in_sublot_tbl. You also need to set the fill attribute column (in_itmpk_fillattr) in the in_itmpk_tbl to a value of 2.

Example Usage

New Item #23 is catchweighted, and Whistle needs to know the various weights associated with the item.

Columns

There are certain rules associated with entries made in some columns. This will provide an overview of what is required to be in the various columns of this table.

in_item_key

The item to be catchweighted.

im_pack_key

This is the pack entry of item to be catchweighted. Catchweighted items must have an entry in this column. Items without pack entries are, generally, considered to be bulk inventory.

ucc128_item

This is a unique item number, used to map the item from the vendor to the item in the ERP system.

wms_ctwght_minwgt

Minimum allowable weight of the item. This entry must be less than or equal to the maximum weight of the field. When there is a value in this field, the netweight field must be 0, and the maximum weight field must be filled out.

wms_ctwght_maxwgt

Maximum allowable weight of the item. This entry must be greater than or equal to the minimum weight of the field. When there is a value in this field, the netweight field must be 0, and the minimum weight field must be filled out. If the ERP system you are using is Infor, this value also cannot be larger than the maximum case weight set up in the ERP system.

wms_ctwght_netwt

Net weight of the item. When there is an entry in this field, the minimum and maximum weight fields must be 0.

wms_ctwght_tare

Weight of the packaging material used for packaging this item/pack. This is the amount to be removed from the total weight of the packages item in order to find the actual weight of just the inventory.

upc_key

Typically unused. This value now comes from the ERP system.

wms_ctwght_scc

Typically unused. This value now comes from the ERP system.

wms_ctwght_freeze

This is the number of days to offset the production date for freeze.

wms_ctwght_peel

This is the number of days to offset the production date for peel.

wms_ctwght_backdt

This is the number of days to offset the production date backwards for backdating.

wms_ctwght_sell

This is the number of days to offset the production date for sellby.

defaultitem

Customer specific entry, not generally used.

boxcode

An entry that permits containers with the same inventory contents to track the tares by tare-group instead of by the item. Customer specific entry, not generally used.

minPieces

This is the minimum number of pieces permitted per case.

maxPieces

This is the maximum number of pieces permitted per case.

minPieceWeight

This is the mMinimum average pieceweight for case (average pieceweight is case netweight / # pieces).

maxPieceWeight

This is the maximum average pieceweight for case.

target_pieces

This is the target number of pieces (how many you're trying to pack) for a case.

ECOLotsOnly

This marks an item for being in an ECO certification. ECO lots are only permitted to use ECO item. (Customer specific entry)