Product Quality Audit

Product Quality Audit

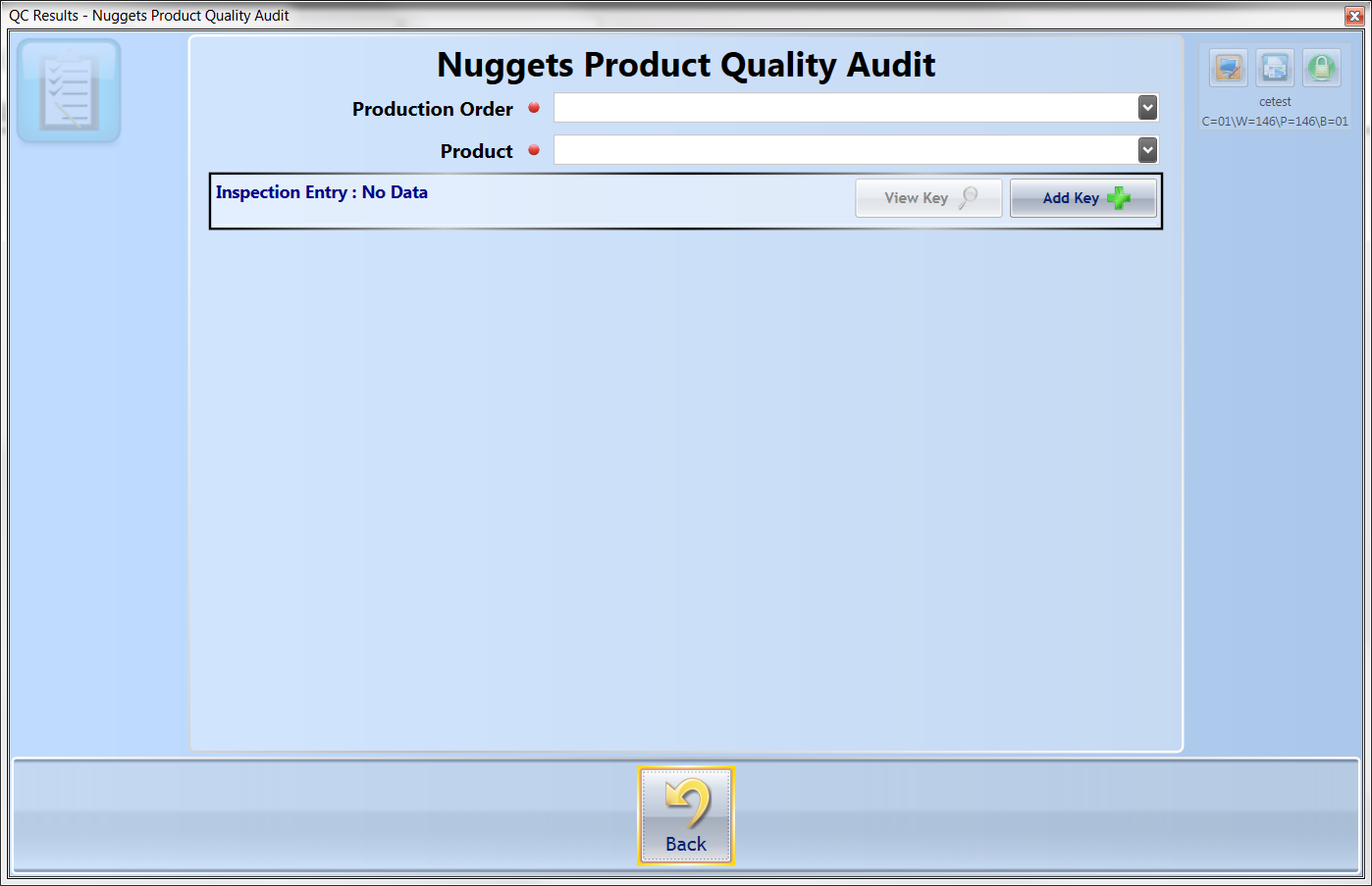

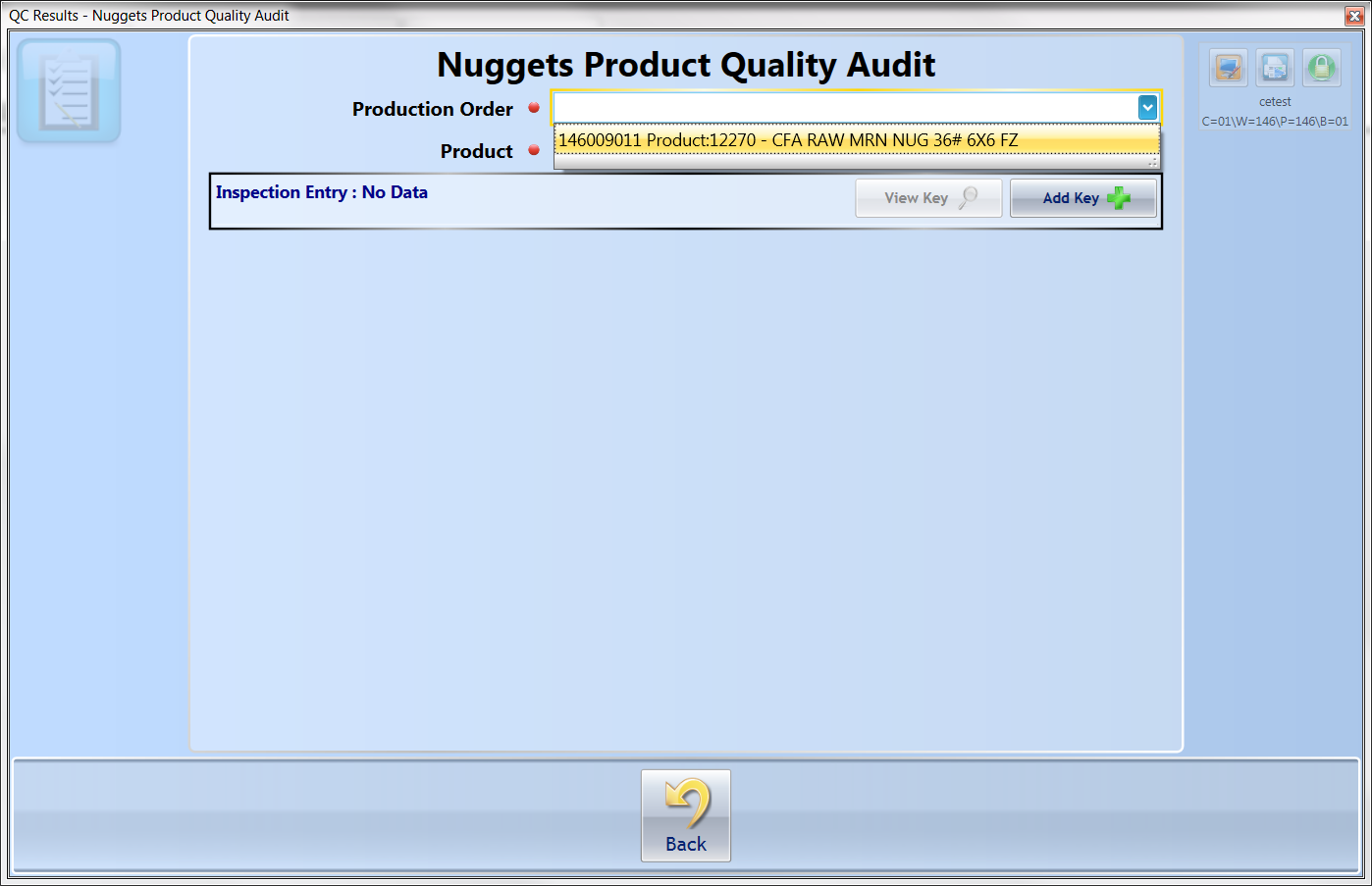

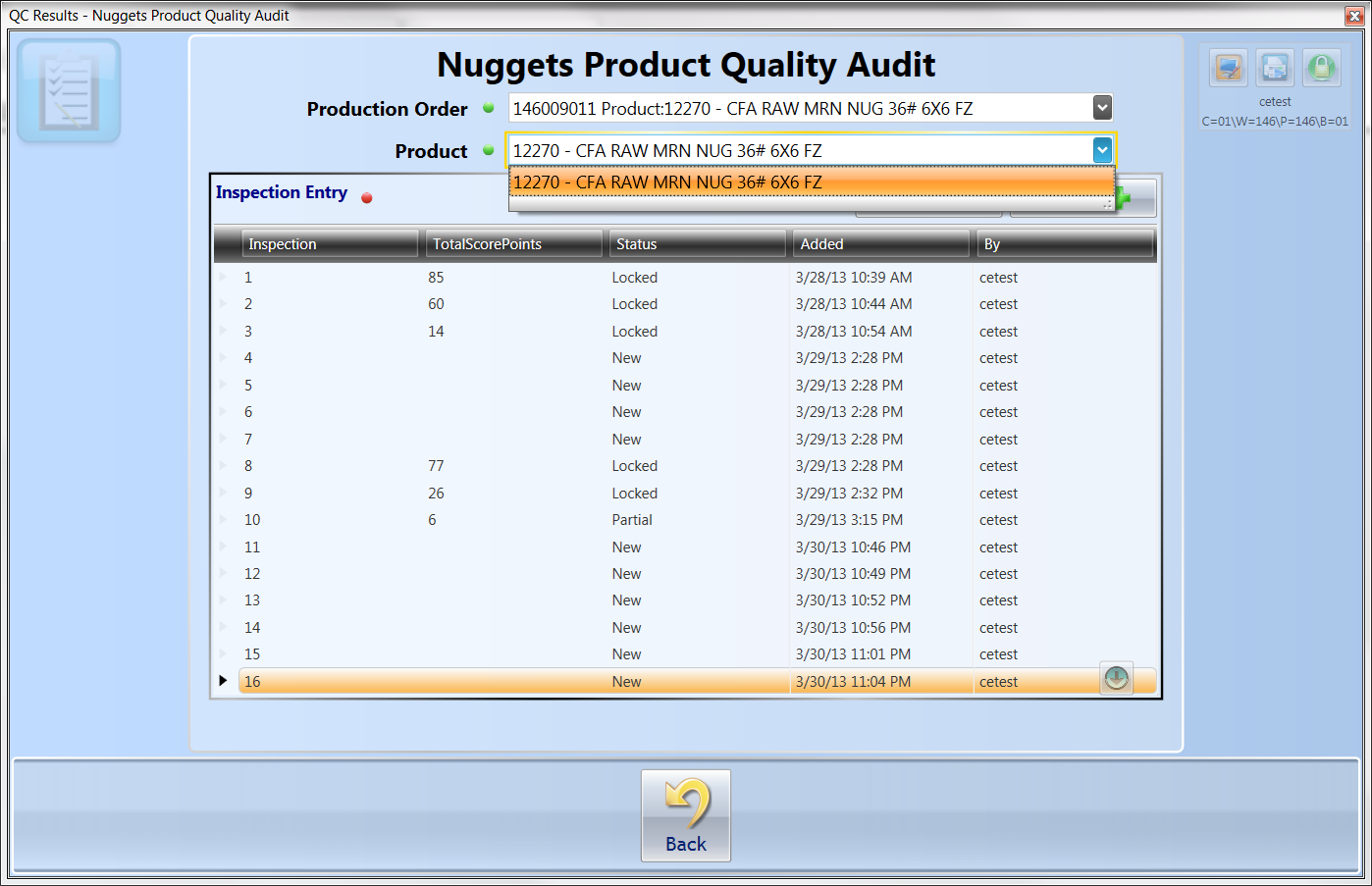

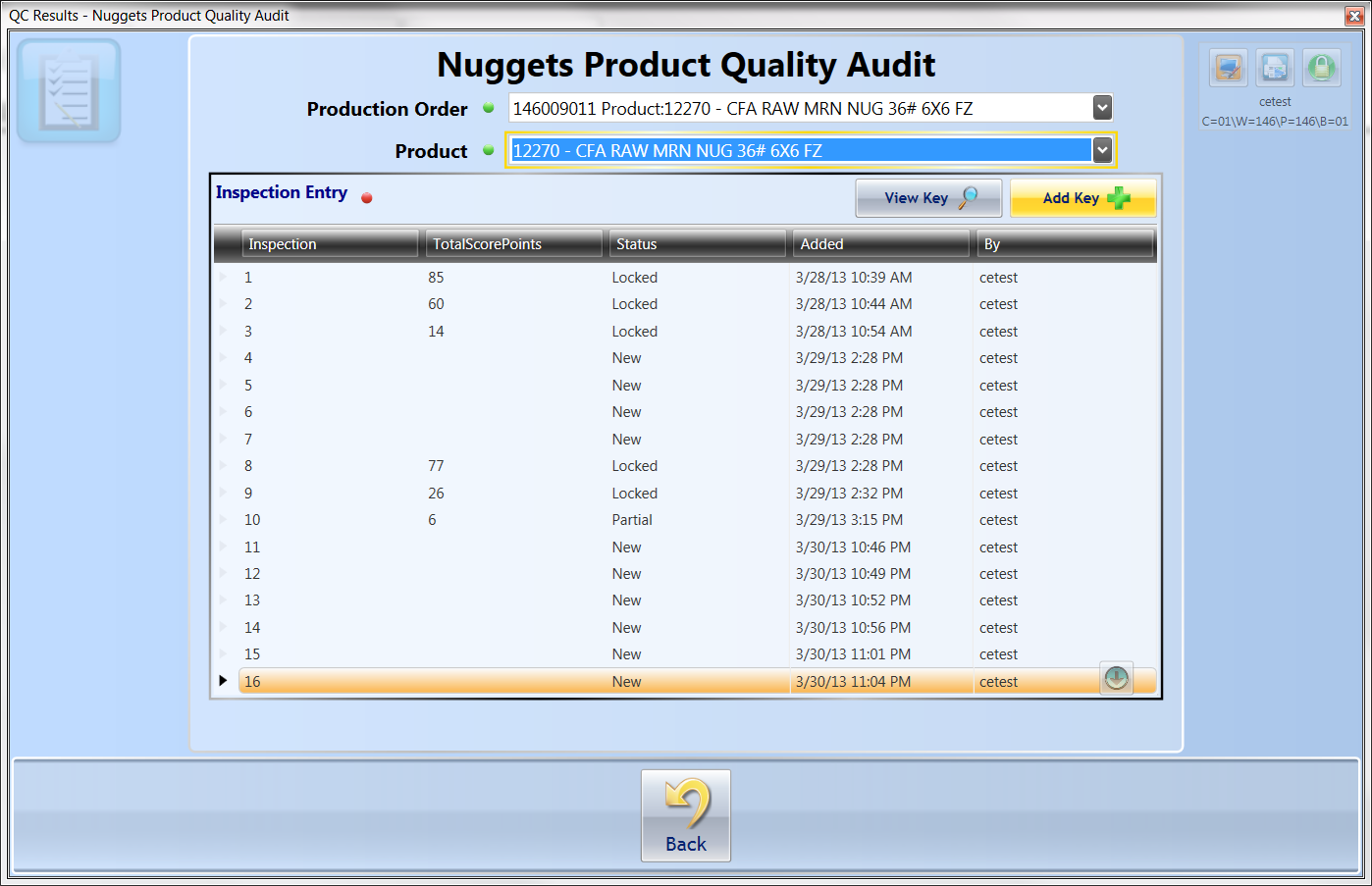

Collecting Product Quality information is presented with a standard header-detail form format. The beginning, header form, allows the user to choose the appropriate order and product for which quality information will be collected. The subsequent detail forms will allow the user to collect sets of data samples under the order/product header.

Header Form

Production Shop Order Field

This field presents a drop-down of each available open Production Shop Order. Choose the order that you wish to begin collecting Product Quality information.

Product Field

This field presents the available Products from the above Production Shop Order that has been selected. Choose the product that you wish to begin collecting Product Quality information.

Add Key Button

Select the Add Key button. This action creates a detail record set to collect Production Quality information in. You will then be taken to the detail form.

Detail Form

There are Four Sections to this detail form:

- #Packaging Section

- #Product Quality Section

- #Product Cost Section

- #Food Safety and Product Liability Section

Packaging Section

This is a list of PASS / FAIL boxes. They include the option of entering a comment and are worth the awarded points found assigned to the quality information being collected.

In this example, the first two boxes have been marked as PASSED.

The third and fourth boxes are marked FAILED and have comments entered into them.

Box Condition Field

Click the Green box if Box Condition passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right.

Box Closure Field

Click the Green box if Box Closure passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right.

Label Field

Click the Green box if Label passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right.

Code Date Field

Click the Green box if Code Date passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right.

Bag Placement Field

Click the Green box if Bag Placement passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right.

Bag Color Field

Click the Green box if Bag Color passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right.

Supplier Code Field

Click the Green box if Supplier Code passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right.

Bag Closure Field

Click the Green box if Bag Closure passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right

Bag Condition Field

Click the Green box if Bag Condition passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right

Bag Weight Distribution Field

Click the Green box if Bag Weight Distribution passed inspection. Click the Red box if it failed. Add a comment, if required, in the empty space to the right

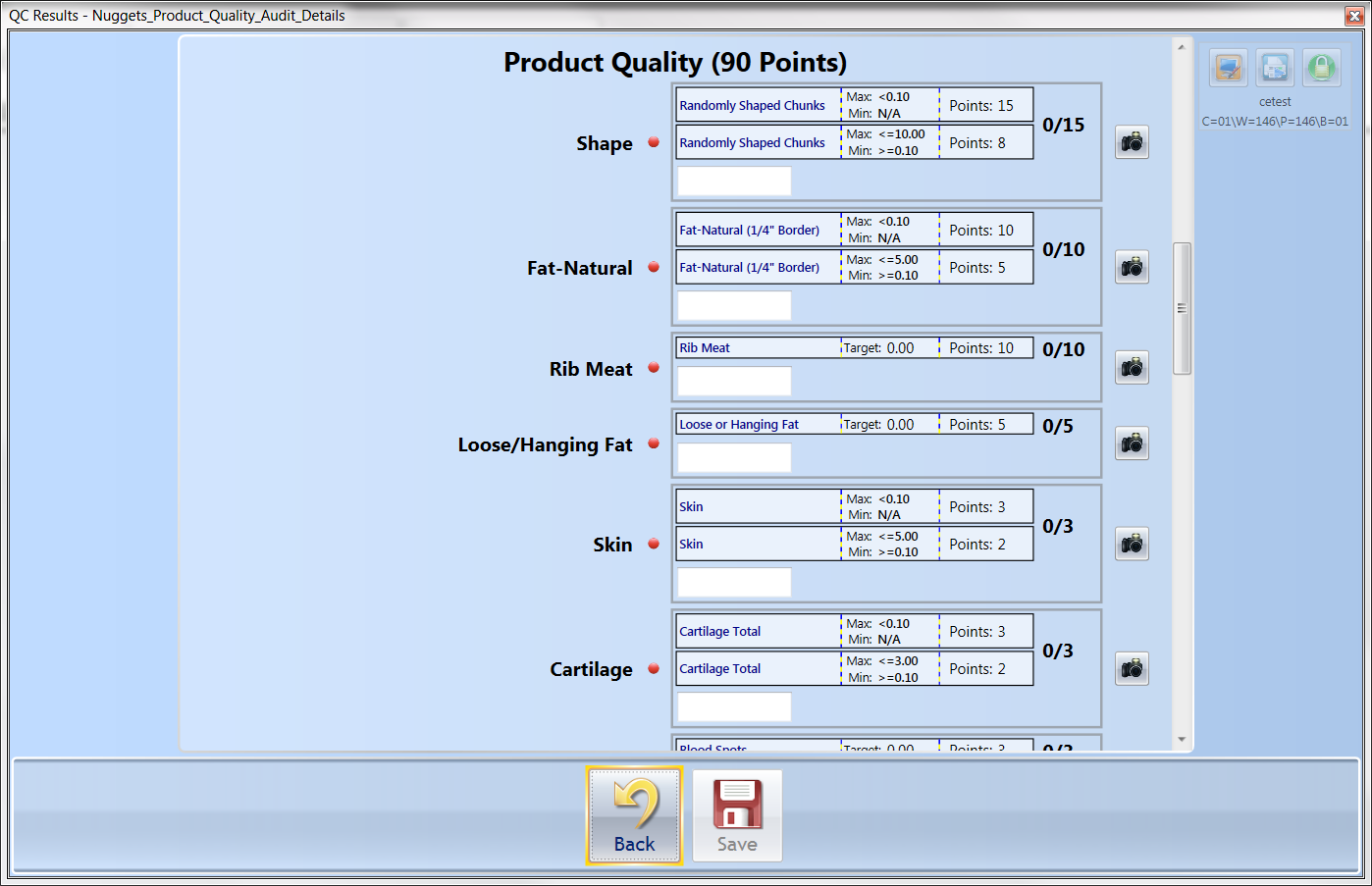

Product Quality Section

This is the Product Quality section. Enter values in each of the boxes.

Shape Field

This field is for entering the number of Randomly Shaped Chunks by size found during the sample inspection.

Fat-Natural Field

This field is for entering the count of nuggets by size found during the sample inspection.

Rib Meat Field

This field is for entering the count of nuggets with rib meat found during the sample inspection.

Loose/Hanging Fat Field

This field is for entering the count of nuggets with loose/hanging fat found during the sample inspection.

Skin Field

This field is for entering the count of nuggets with skin by size found during the sample inspection.

Cartilage Field

This field is for entering the count of nuggets by size with cartilage found during the sample inspection.

Blood Spots Field

This field is for entering the count of nuggets with blood spots found during the sample inspection.

Bruises Field

This field is for entering the count of nuggets with bruises by size found during the sample inspection.

Cut-Through Field

This field is for entering the count of nuggets with cut-through greater than .75 inches found during the sample inspection.

Overscalding Field

This field is for entering the % of nuggets with overscalding found during the sample inspection.

Spice Application Field

This field is for entering the % of nuggets with spice application found during the sample inspection.

Fish Eyes Field

This field is for entering the % of nuggets with fish eyes found during the sample inspection.

Freeze Spots Field

This field is for entering the % of nuggets with freeze spots found during the sample inspection.

Membrane Field

This field is for entering the % of nuggets with membrane found during the sample inspection.

Skin Abrasions Field

This field is for entering the % of nuggets with skin abrasions found during the sample inspection.

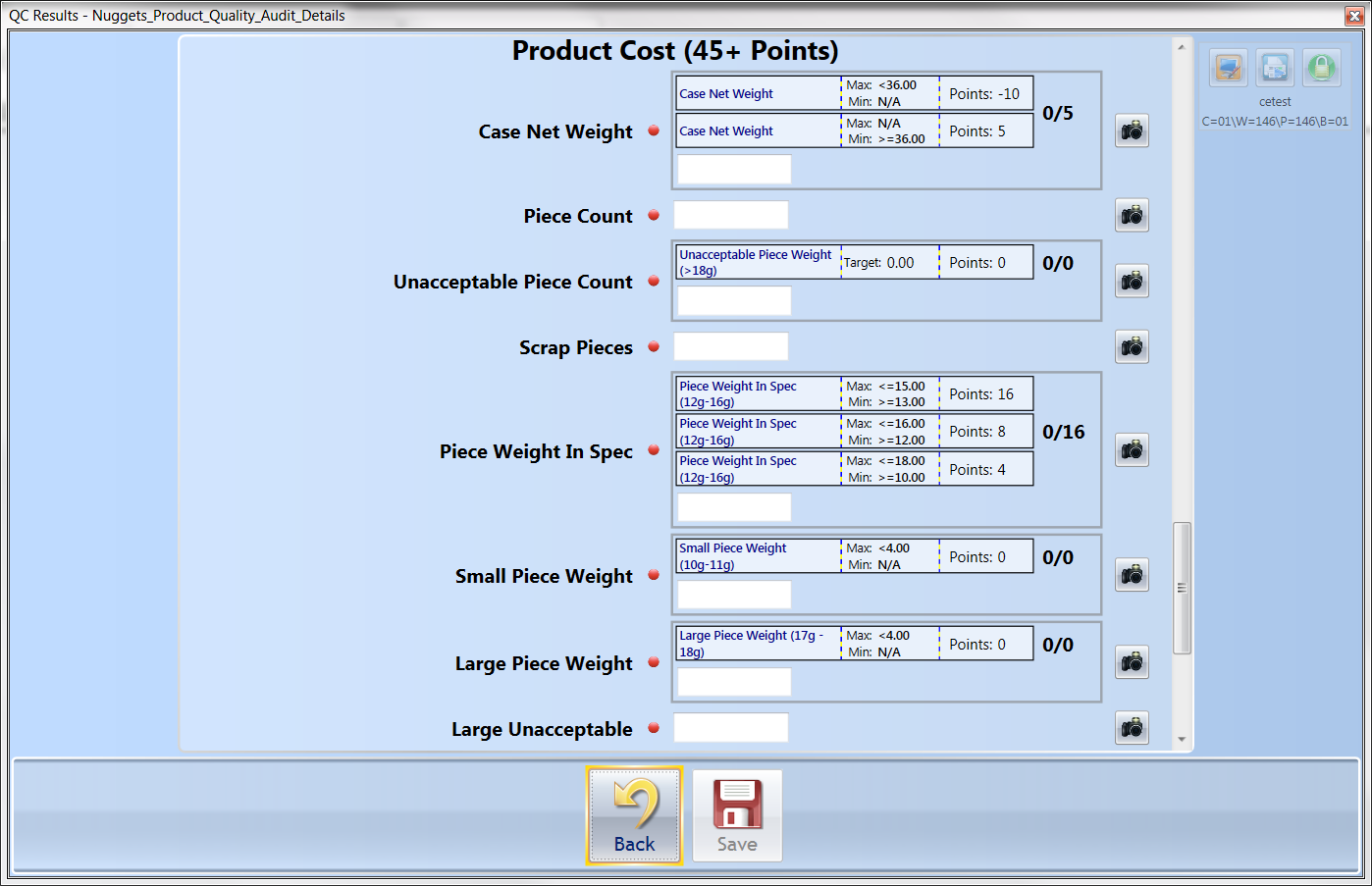

Product Cost Section

This is the Product Cost section. Enter values in each of the boxes.

Case Net Weight Field

This field is for entering the net weight of the cases found during the sample inspection.

Piece Count Field

This field is for entering the piece count found during the sample inspection.

Unacceptable Piece Count Field

This field is for entering the unacceptable piece count found during the sample inspection.

Scrap Pieces Field

This field is for entering the number of scrap pieces found during the sample inspection.

Piece Weight in Spec Field

This field is for entering the % of pieces in spec found during the sample inspection.

Small Piece Weight Field

This field is for entering the % of small pieces found during the sample inspection.

Large Piece Weight Field

This field is for entering the % of large pieces found during the sample inspection.

Large Unacceptable Field

This field is for entering the % of large unacceptable pieces found during the sample inspection.

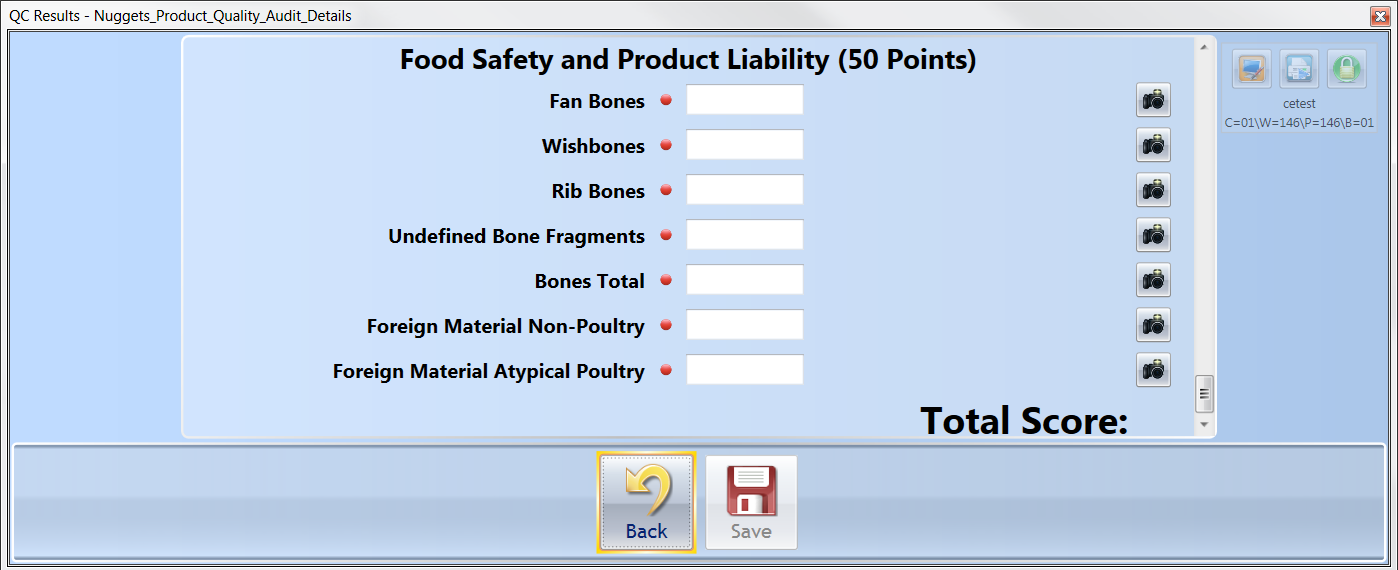

Food Safety and Product Liability Section

This is the Food Safety and Product Liability section. Enter values in each of the boxes.

Fan Bones Field

This field is for entering the number of Fan Bones found during the sample inspection.

Wishbones Field

This field is for entering the number of Wishbones found during the sample inspection.

Rib Bones Field

This field is for entering the number of Rib Bones found during the sample inspection.

Undefined Bone Fragments Field

This field is for entering the number of Undefined Bone Fragments found during the sample inspection.

Bones Total Field

This field is for entering the total number of Bone pieces found during the sample inspection.

Foreign Material Non-Poultry Field

This field is for entering the number of Foreign Materials found that are non-poultry related during the sample inspection.

Foreign Material Atypical Poultry Field

This field is for entering the number of atypical poultry related Foreign Materials found during the sample inspection.

Return to QC Results